Industrial & Manufacturing

Strict QC — From Material to Final Packing

Advanced inspection processes ensuring every exhaust system meets our exacting standards through comprehensive testing and validation

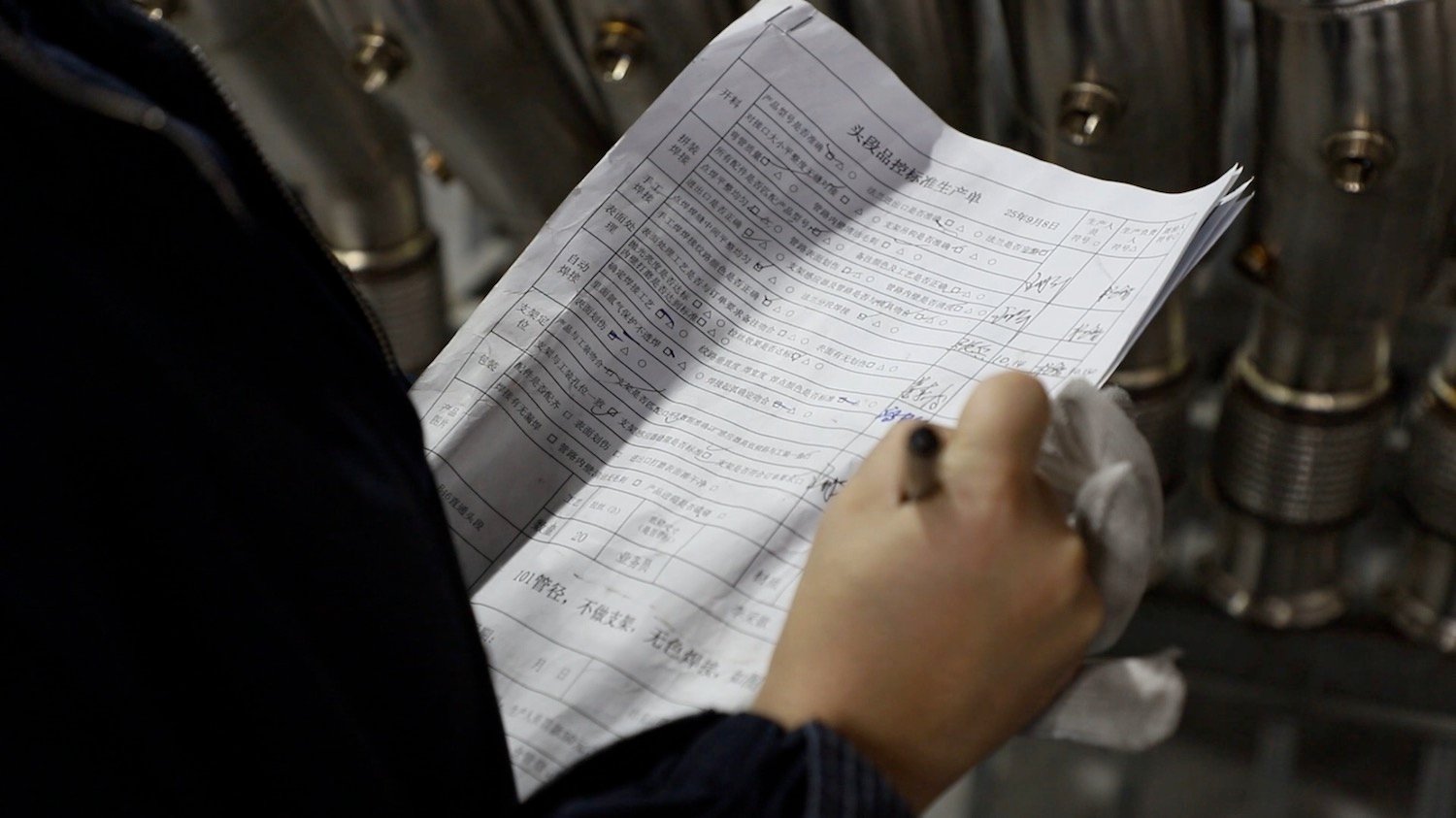

Quality Control Process

All titanium and stainless steel sheets are inspected for thickness, flatness, and surface finish before cutting. Ensure consistent material quality.

Each welded part is placed on a 3D fixture to verify fitment and dimension accuracy.

Guarantees perfect alignment.

Every exhaust system passes a smoke-pressure test to confirm there’s no leakage at any joint. 100% leak-free assurance.

Before packing, QC checks the welds, polishing, and logo position for a flawless appearance. Every detail counts.

All clamps, bolts, and gaskets are verified for completeness before sealing the box. Ready to install on arrival.

Each product is labeled, photographed, and signed off by QC before leaving the factory. Quality guaranteed from start to finish.

How it works

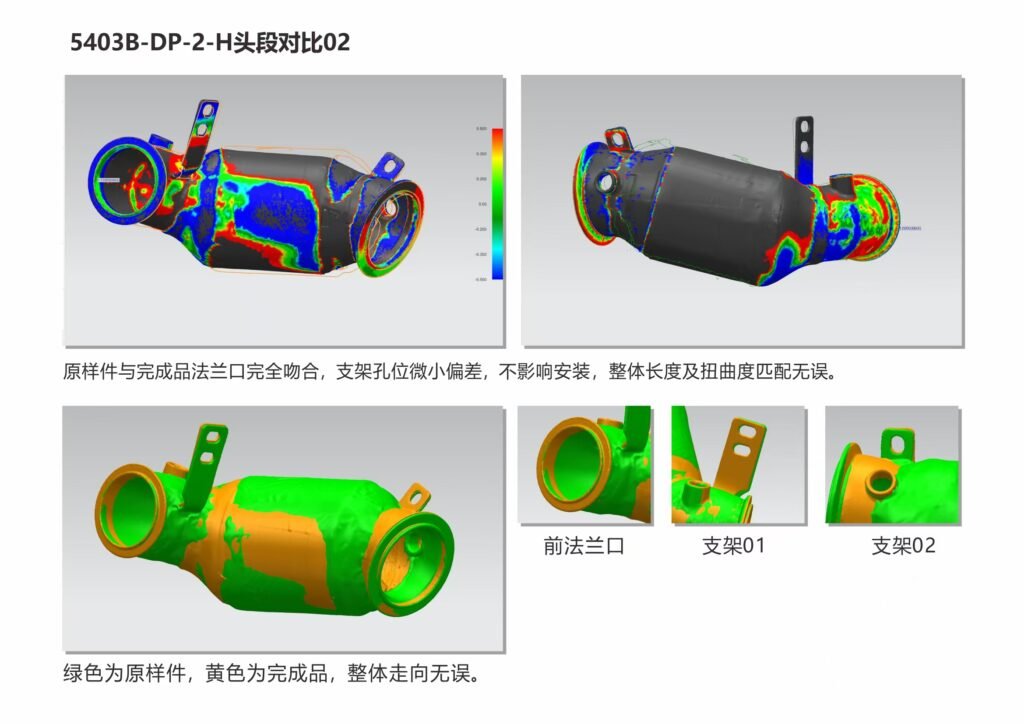

3D Precision Comparison

We use advanced 3D scanning and digital comparison to verify dimensional accuracy between customer samples and our mass production exhausts — ensuring 100% consistency.

Sample 3D Scanning

We 3D scan the customer’s original exhaust to capture precise geometry data as the benchmark model.

Production Sampling

From the production batch, 5 sets are randomly selected and scanned under identical settings.Ensures consistent data collection.

3D Data Comparison

We overlay both scans in software to compare every angle, curve, and weld position.Deviation tolerance within ±0.2 mm.

Consistency Verification

Only when the color map shows full overlap (green zone) will the batch be approved for shipment.Guarantees product accuracy before delivery.

Meet Our QC Team

Quality is not inspected at the end — it’s built into every process.

Head of Quality Control

3D Data Analyst

Fixture & Welding Inspector

Final Inspection & Packing Supervisor