Industrial & Manufacturing

Performance & Sound Redefined – Titanium and SS304 Systems for AUDI,BMW, BENZ,Porsche, McLaren, Ferrair,Lamborghini and More

We will print out 3d drawing and make fixture for accuracy and strict confidentiality.Enjoy the benefits of our reliable and secure customization services.

We offer sample customization, ensuring every detail meets your requirements. Our experienced team uses advanced technology to replicate your samples with high quality and confidentiality.

We offer precise on-car prototype customization. Our skilled team ensures top-quality results using advanced technology. We meet all your customization needs.

3D Scan & Precision Development

We start every exhaust development from 3D scanning of the OEM exhaust system

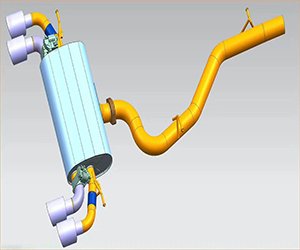

Based on the scanned data, our engineers design the upgraded exhaust system in CAD — optimizing flow, weight, and sound.

The production fixtures are then laser-cut from the CAD drawings to guarantee repeatable accuracy during welding and assembly.

From prototype to mass production, this workflow ensures 100% OEM fitment and stable quality for every unit delivered.

3D Scan & Collaborative Design

Every exhaust development begins with precise 3D scanning of the vehicle’s chassis and OEM exhaust system.

This ensures that all pipe routing, hanger positions, and clearances are captured with millimeter-level accuracy.

Based on the scanned chassis data, our engineering team combines it with the client’s design concept and performance goals — whether it’s for sound tuning, flow optimization, or aesthetic style — to create a fully customized exhaust solution.

Using CAD modeling, we translate the concept into detailed production drawings.

These files are then used for laser-cut fixtures and CNC tooling to ensure precise positioning, consistent quality, and 100% OEM fitment during mass production.

5-Axis Machining for Precision Fixtures

To ensure the perfect installation accuracy of every exhaust system, we manufacture precision welding and assembly fixtures using our in-house 5-axis CNC machining center.

Each fixture is produced according to the CAD data generated from the 3D-scanned chassis and exhaust model.

This guarantees that every mounting point and pipe position matches the original OEM coordinates with millimeter precision.

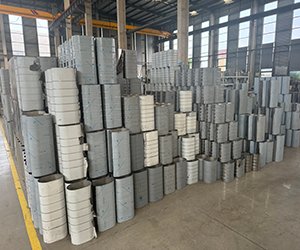

These fixtures are not part of the exhaust itself — they serve as the foundation for consistent alignment and welding accuracy during mass production, ensuring 100% fitment for every system produced.

Engineering & Manufacturing Capability

Built from Precision, Powered by Innovation

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

Fermentum ornare vel vestibulum suscipit sed magna efficitur.

OEM/ODM Customization Services

Make It Your Brand’s Signature System

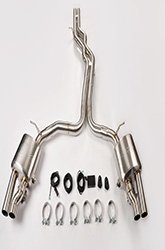

Our Axle-Back & Cat-Back System

Performance. Precision. Personality.

Quality Control & Testing

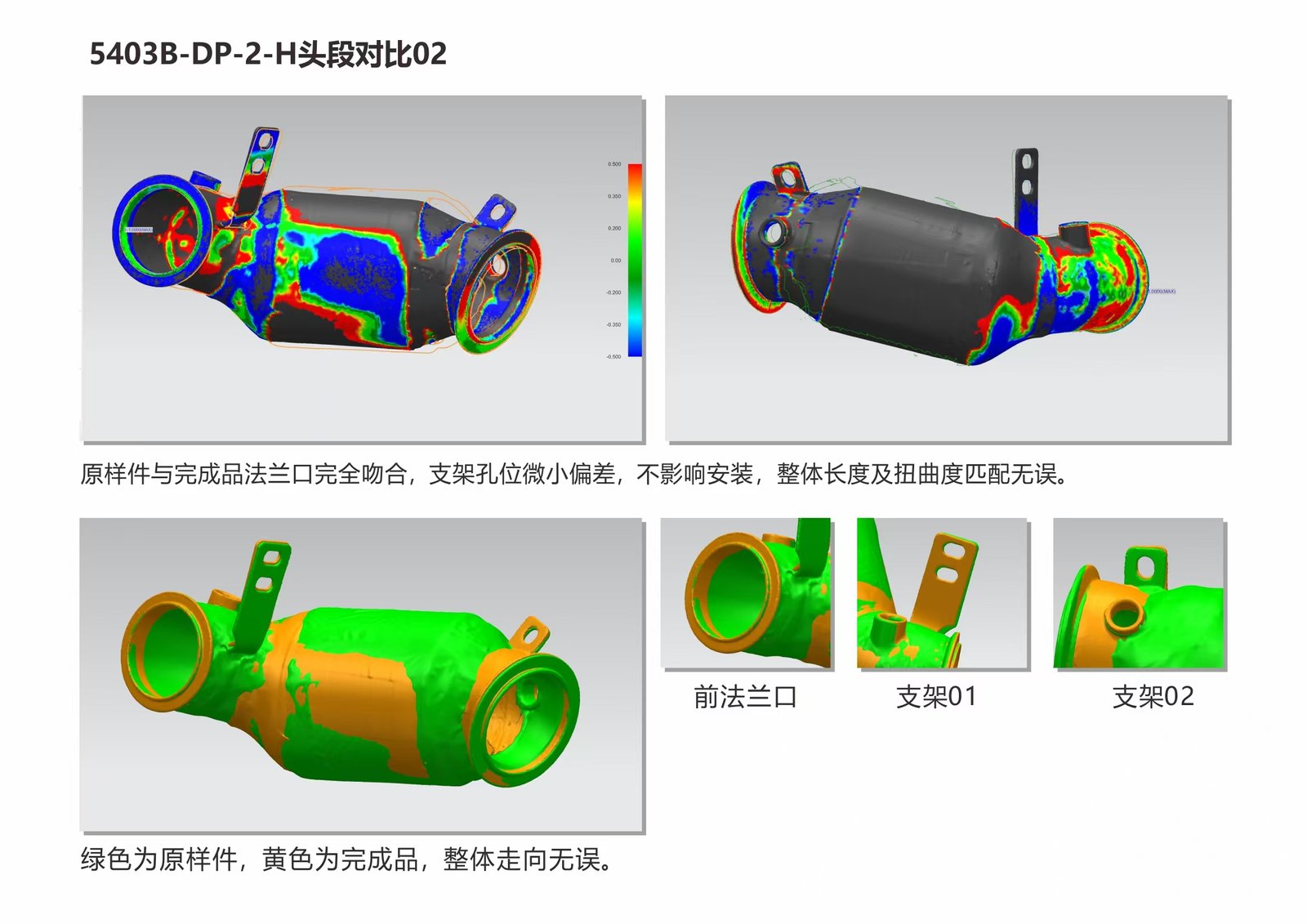

3D scan the original sample data and our prototype sample data, then perform 3D data alignment.

All exhaust systems undergo a smoke test before leaving the factory to ensure there are no leaks.

Welds, surface finish, complete accessories and packaging integrity

Description

Our axle-back and cat-back exhaust systems are precision-engineered for tuning brands and OEM developers who value performance, reliability, and customization. Each system is designed using 3D scanning and OEM chassis data to guarantee perfect fitment and optimized flow for maximum horsepower and torque.

Available in titanium, SS304, or hybrid carbon-titanium construction, our systems feature TIG welding, CNC flanges, V-band connections, and optional electronic or vacuum-controlled valves. Every piece reflects meticulous craftsmanship and can be tailored with your logo, sound preference, and exclusive tip design.

Our Solutions & Benefits

- 100% OEM-fitment verified by 3D scanning

- Lightweight titanium & SS304 materials

- Electronic / vacuum valve options

- Deep, refined exhaust tone with no drone

- Fast lead time – sample in 15–20 days

- Full OEM/ODM customization available

- CNC-machined flanges and precision V-bands

- Custom tip designs (carbon, burnt blue, titanium)

- Quality inspection for every unit

- Global delivery with reliable packaging

Interested in our exhaust systems?

Send us your customization idea ,our team will provide a detailed quotation and technical support within 24 hours

Need more help?

Looking for a custom exhaust solution or OEM cooperation?

Our engineering team can support you from concept to production — including 3D scanning, CAD design, and prototype sampling.

Let’s build your brand’s next performance system together.

+8615267011577

+8615267011577