INDUSTRIAL & PERFORMANCE ENGINEERING

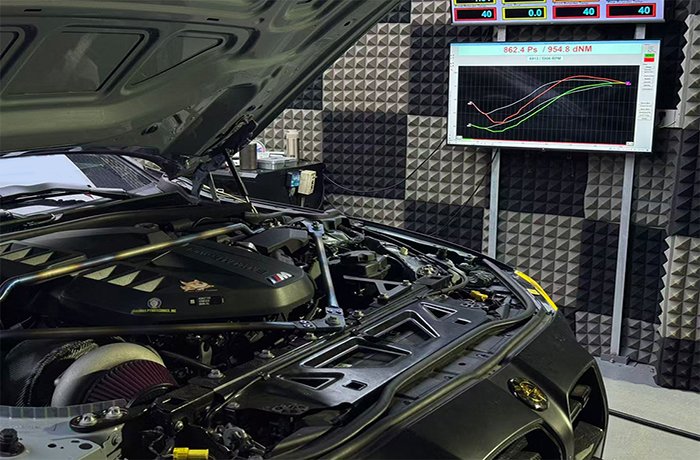

Custom Exhaust Manifolds / Headers · OEM Fitment · Dyno-Proven Results

Every manifold starts from OEM car 3D data, ensuring precision fitment and performance balance.

Each jig is CNC-built and test-fitted to guarantee perfect installation on every car.

Exclusive designs for each client — all data, tooling and drawings remain protected.

Who we are

Built on Real Car Data

We start by 3D scanning the OEM manifold or header to capture precise geometry.

Based on the scanned data, our engineers create CAD models and CNC fixtures to ensure every piece installs just like OEM — perfectly aligned, every time.

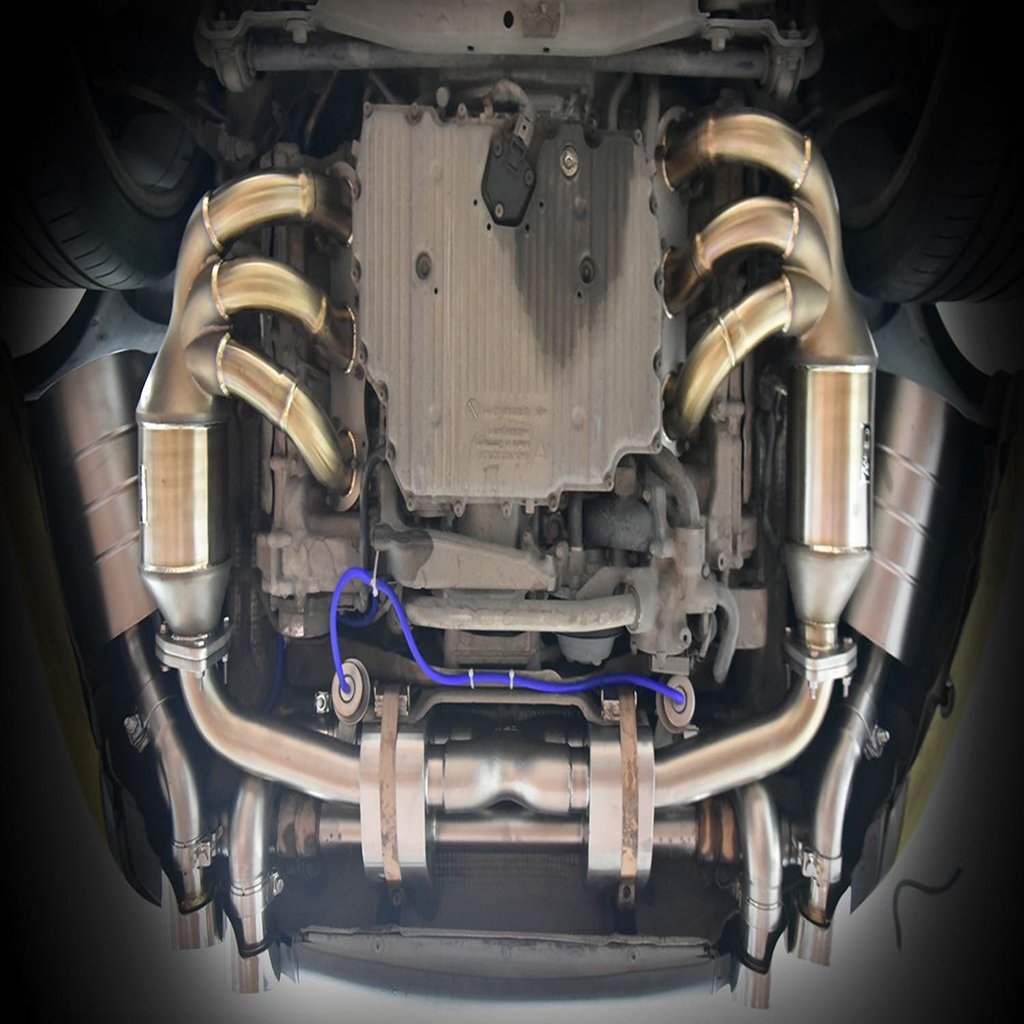

CNC Billet Flange – Engineered for Precision & Strength

We use 5-axis CNC machining to mill each port transition to match OEM cylinder-head profiles, ensuring a smooth gas flow and leak-free sealing surface.

The bolt holes are precisely indexed to OEM patterns, eliminating any misalignment during assembly.

3D Print turbo manifold

3D-printed exhaust manifold enables smoother internal channels and eliminates the constraints of traditional casting or welding

How it works

Manufacturing Excellence

Five dedicated production lines with advanced technology and experienced QC professionals ensuring consistent quality

CNC Precision Machining

Computer-controlled precision cutting and forming for perfect fitment and dimensional accuracy across all manifold components.

Casting, wire cutting, 3D printing collector

Our collectors are manufactured using a combination of precision casting, high-accuracy wire cutting, and advanced 3D printing technology.

This hybrid process ensures optimal flow efficiency, superior strength, and perfect geometric balance.

Quality Control

5+ years experienced QC professionals conduct dual testing on all welds and 100% dimensional inspection before delivery.

Customize made

We offer complete OEM/ODM solutions—send us your 3D data, idea, or sample, and we will build it from concept to production.

Exclusive design protection and confidentiality guaranteed.